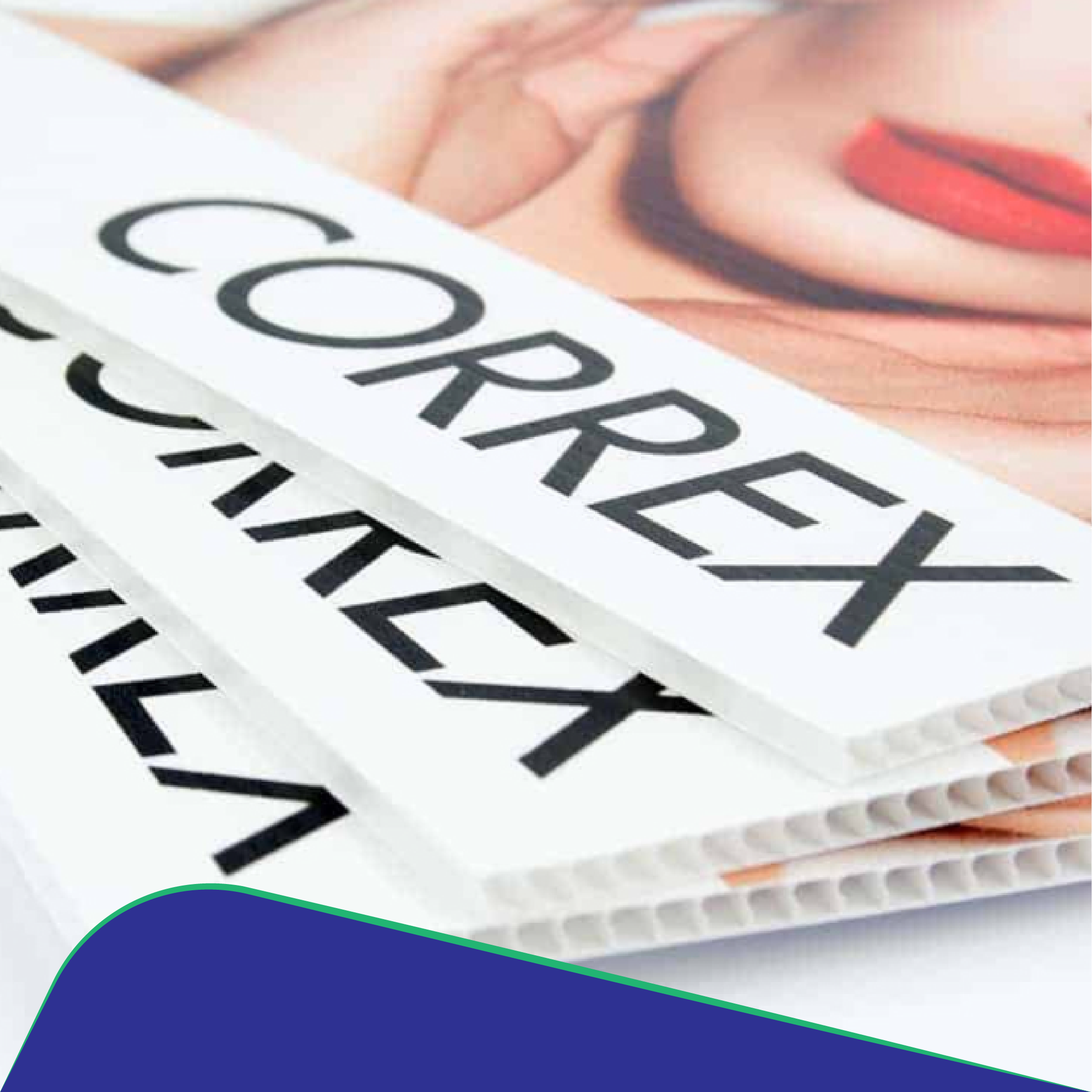

Correx Board

SKU

corex

Category Corex Board

Correx Board

Print: Full colour

Side: Front only

Thickness: 3mm

Size: A2 | A1 | A0

R172,50 – R920,00Price range: R172,50 through R920,00

Please note that all designs must be supplied in High Resolution with a minimum of 3mm bleed and cutting lines. Visit our “learn more” page for more information.

Corex board, also known as corrugated plastic board or corriboard, is a lightweight, durable, and versatile material used for various applications. It consists of a plastic sheet with hollow flutes (ribbed structures) running between two flat surfaces, which gives it strength and flexibility. Here are some key characteristics and uses of Corex board:

- Material Composition: Corex board is typically made from polypropylene (PP) or polyethylene (PE), which are both durable plastics. The fluted structure between the outer layers provides strength while keeping the material lightweight.

- Durability: It is resistant to moisture, chemicals, and impacts, making it suitable for both indoor and outdoor use. It can withstand various weather conditions, including rain and sunlight.

- Versatility: Corex board is widely used in signage, packaging, construction, and advertising industries. It is easy to cut, fold, and manipulate, allowing for custom shapes and designs.

- Signage and Advertising: Due to its smooth surface and ability to accept printing, Corex board is popular for signage and advertising boards. It can be printed directly with graphics, text, or images, making it ideal for temporary and promotional signage.

- Packaging: It is also used for lightweight packaging and protective layering in shipping due to its cushioning properties and ability to absorb shocks.

- Construction and DIY Projects: Corex board can be used in construction for temporary partitions, formwork, or as protective coverings. It is also used in DIY projects for crafts, displays, and organizational tools.

| Size | A4, A3, A2, A1, A0 |

|---|---|

| Board Thickness | 3mm, 5mm |